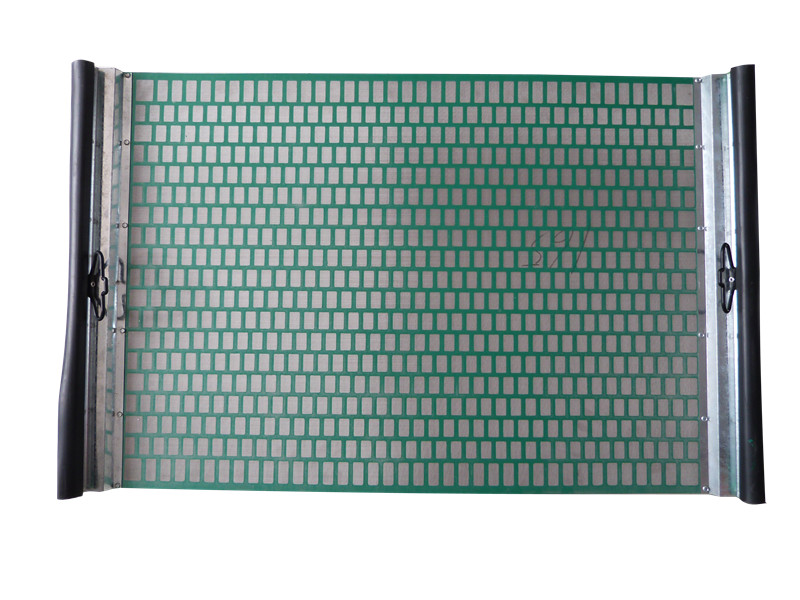

Vibrating screens are essential machinery to allow miners to separate and classify minerals after they are milled, and General Kinematics, a family-owned equipment supplier based in Crystal Lake, Illinois, is introducing a line of more efficient screens to Latin Amerca.

These two-mass screens can significantly reduce energy use, installation and maintenance costs, and unscheduled downtime, and since the optimization of operations is a priority for the Latin American mining industry, this technology could be a great help for companies to eliminate production bottlenecks and increase output. Mi-Swaco

BNamericas spoke with Mauricio Saavedra, sales manager for South America at the company, to find out more about its screens.

BNamericas: What is the importance of screeners in the industry?

Saavedra: Many industrial applications require equipment that vibrates and releases material, such as screens that are manufactured at an industrial size to separate material by diameter. These machines must be fed continuously to continue vibrating and separate the coarse material from the fine. Almost all manufacturers use the same technology, but for decades we have been using a different technology called two-mass.

BNamericas: How is this technology different?

Saavedra: Equipment that is constantly vibrating for a long period usually destroys itself. The advantage of screens with two-mass technology is that they vibrate in a different way and the equipment doesn’t fall apart. It also has greater production capacity and lower energy consumption because they use smaller motors and cause fewer plant stoppages.

It’s also more efficient, that’s why there are already thousands of them in the world, although in Latin America there are still only very few in operation because mining continues to use brute-force vibrating equipment, which is old technology that eventually self-destructs.

BNamericas: What are the benefits of using two-mass screens in mining plants?

Saavedra: It’s a radical change, since companies are used to sending screens and conventional brute-force equipment to maintenance workshops or having them self-destruct, which creates a risk for workers. Many customers have an army of mechanics to make repairs and have plenty of spare parts in their warehouses.

Two-mass equipment doesn’t need to be changed every six months like brute-force equipment does, so there’s less unscheduled maintenance and less downtime at the mining plant, which is equivalent to several million dollars per day. With this equipment you can meet production plans.

BNamericas: Why is it claimed that you can help reduce operating costs?

Saavedra: One of the most important things for a mining company is the availability of the plant, since it has to operate 24 hours a day, 365 days a year, producing copper or iron, but equipment failures, either in the mill or in screening or other areas, means the availability of the plant is reduced to 90%. It’s a challenge for maintenance managers.

Two-mass technology improves availability and increases production days, which translates into profits for companies.

BNamericas: What experience is there in Chile with the use of two-mass screens?

Saavedra: We’re installing the first screen in a copper mining plant that will begin operating in January next year. It’s one of the largest projects we have under construction. In San Juan province in Argentina, the Josemaría project is using equipment with two-mass technology, since its engineers know that this technology eliminates maintenance problems, unexpected stoppages and increases productive capacity.

BNamericas: Why haven’t these screens become widespread in Chilean mining?

Saavedra: Technological advances in mining take time. Decisions are slow because of their habit of operating in the same way for decades. There’s fear of incorporating new technologies.

BNamericas: How many units have you already sold?

Saavedra: We have more than 60,000 pieces of equipment installed in more than 45 countries for different industries and the market continues to grow. As the mining industry has expanded, the size of equipment and screens has also increased.

BNamericas: Where is the equipment manufactured and in which mining jurisdiction is it most widely used?

Saavedra: The factory and main plant is in Crystal Lake in the United States. They are designed and manufactured there. The teams have already been operating for about 15 years in places such as the United States, Europe and Asia and we’re now entering the Latin American market.

BNamericas: How is two-mass technology mechanically more efficient?

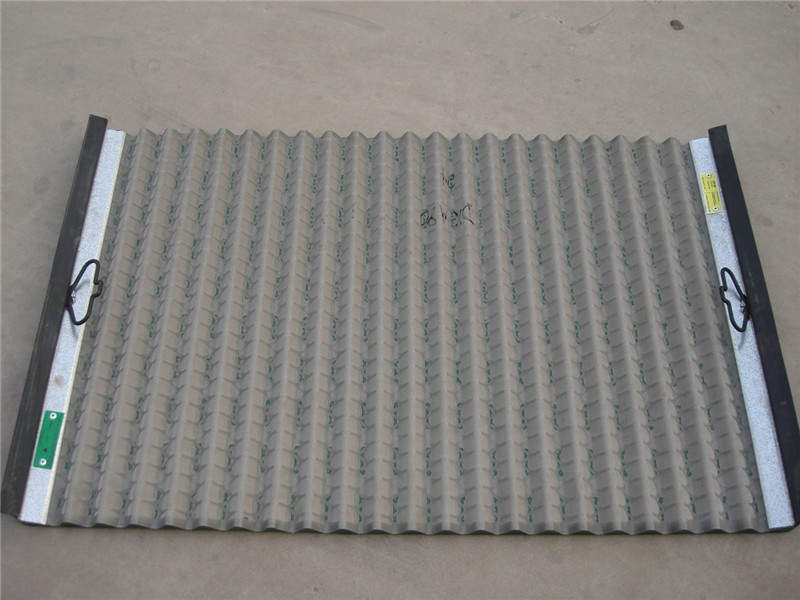

Saavedra: The equipment vibrates from above and below with springs, but the lower part, since it has no mechanical tension, doesn’t self-destruct. It also has an efficient screener that separates the material by size. Despite having lower electrical power consumption, the equipment has a long lifecycle and it’s very smooth when starting and stopping. It’s used in mining, in smelting with hot material and even in garbage management to separate small and large or light and course waste.

Two-mass screen installed at Copper Mountain plant, Canada.

Subscribe to the leading business intelligence platform in Latin America with different tools for Providers, Contractors, Operators, Government, Legal, Financial and Insurance industries.

The Canadian miner is implementing a cost reduction plan after its acquisition of Yamana Gold.

Latin American steel and mining companies are signing power purchase agreements as part of sustainability efforts, but coal will also remain releva...

Subscribe to Latin America’s most trusted business intelligence platform.

Get critical information about thousands of Mining & Metals projects in Latin America: what stages they're in, capex, related companies, contacts and more. Request Demo

Get critical information about thousands of Mining & Metals companies in Latin America: their projects, contacts, shareholders, related news and more. Request Demo

Subscribe to BNamericas to find news reports, information on projects and contact information relating to thousands of companies that drive business in Latin America.

Mud Shale Shakers Request a demo and access exclusive content