In injection molding, material is fed through a hopper into a barrel where a reciprocating screw mixes and melts the material then injects it into a mold.

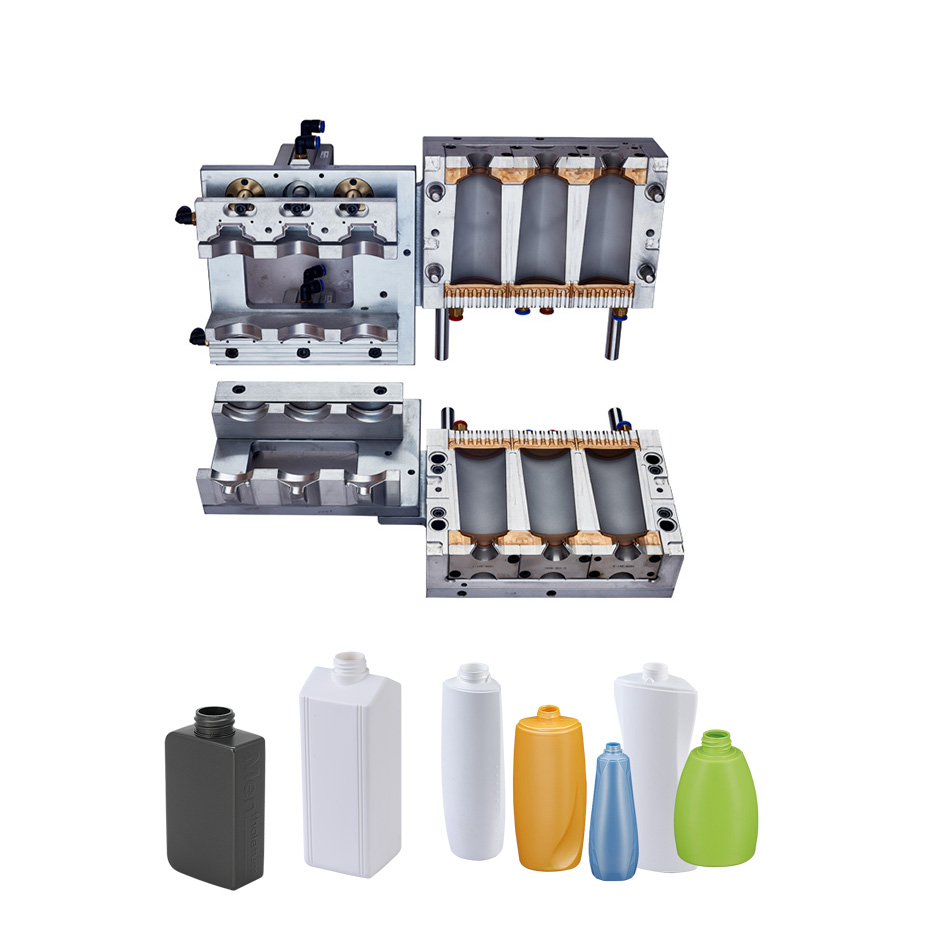

A well-maintained injection molding machine will improve uptime, decrease cycle time and extend the life of the machine. Bottle Blow Mold

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.

Here’s how to get the most out of your stationary mold vents.

Here’s what you need to know to improve the quality of your parts and to protect your molds.

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

AI Integrated Into Injection Molding Process Control

Freeform Injection Molding Eases the Path to Medical Device Product Testing

Arburg Opens Subsidiary in Vietnam

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

Ultrasonic Inserts and Heat Staking Kits for Thermoplastics

LS Mtron Opens Division in Mexico

Free, Assisted Data Transfer for Injection Molding Monitoring and Control Platform

Medical Molder, Moldmaker Embraces Continuous Improvement

Metal Injection Molding Line Launches

Melt Temperature Measurement Technology Acquired

Is There a More Accurate Means to Calculate Tonnage?

Cold Deck for LSR Molding

Fakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Internal Gas Pressure Molding Offers Sustainability Benefits

Structural Foam Injection Molding Line Extended

Upgraded Low-Pressure Foam Presses With Elevated Bases

Fakuma: Wittmann Battenfeld to Launch Machine Line at Friedrichshafen Fair

Water Injection Beats Gas Assist in Lightweighting Car Door Panel

Linde Sells Industrial Gas Business to Messer Group

Sumitomo’s Theme: Productivity + Flexibility + Reliability

New Physical Foaming Process for Injection Molding

Lifetime Achievement Awardee Honored For Over 30 Years of Advances in Automotive Molding

Mack Molding Adds ‘Largest Press in New England’

Molder Opts for Machine Flexibility for Complex Jobs

Fakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Video: Ultradent Bags Both Hot Shots Prizes at PTXPO 2023

New Multicomponent Injection Molding Machine Line Launches

Mold, Hot Runner, Digitization and Process Monitoring at K 2022

ZAG Equipment Sales Partners with Portugal’s Plasdan of Portugal

Multicomponent Mold Combines Capping and Unscrewing Functions for Pharma Closure

Dual Injection Units on a Smaller, Electric Press for 2K Medical Molding

Servo-Hydraulic Machine Range Adds Multicomponent Models

Larger Capacity Auxiliary Injection Unit Introduced

Nozzle Shutoff Shuts Down Drool

Cold Deck for LSR Molding

LSR Advances in Dispensing, Tooling and Automation

Fakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

New Machine Range Features Adjustable Clamp for Micromolding

Injection Machines Use Novel Two-Stage Molding System

K 2022: LSR Cell Makes Four Different Lids With Each Cycle

Finding a Niche in LSR Tooling

New LSR Cold-Runner Package at K 2022

In-Mold Labeling Applied to Medical

Kurz Opens New Plant in Vietnam

Borealis and Bockatech Showcasing Ultra-Lightweight Reusable PP Cups

New In-Mold Labeling System Launches at K 2022

New In-Mold Labels Enhance Recycling of PP Containers

DuraTech Industries Licenses TactoTek’s Injection Molded Structural Electronics (IMSE)

Packaging Project Combines Thin Walls, Recycled Content and High Speeds

Muller Technology Announces New COO

Get Ideas from IMDA Award Winners In IML, IMD & In-Mold Electronics

Fakuma: Wittmann Battenfeld to Launch Machine Line at Friedrichshafen Fair

New Package Concept Offers Relief from PP Shortages & Soaring Prices

New Machine Range Features Adjustable Clamp for Micromolding

Innovative Micro-Molding From Minnesota Machine Shop

Matrix Tool: Welcome to the Family

X2F and Covestro Collaborate on Innovative In-Mold Electronics for Automotive Lighting

Matrix Tool Wins Inaugural Hot Shots Competition

Fakuma: Wittmann Battenfeld to Launch Machine Line at Friedrichshafen Fair

Westfall Technik Opens Medical Molding Facility

Freudenberg Medical Adds Six Machines

MTD Micro Molding Completes Expansion

Fakuma Show Goes On (Digitally) for Wittmann Battenfeld

Micromolder Makuta Adopts Carbon 3D Printing

K 2019 Preview: Injection Molding Goes for the ‘Green’

IPEX Opens Injection Molding Facility in North Carolina

Adaptive, Automatic Process Control for Injection Molding

Wittmann Finds Battery Partner for Direct Current (DC) Molding Machine Concept

Fakuma 2023: More Details on New Machine Line

Fakuma 2023: New Hybrid Machine Launches

Injection Compression Molding as Alternative to Thermoforming

Fakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Custom Injection Molder Plugs into All Electric Machines

Arburg Marks Anniversary with New Generation of Machines

Compact Hybrid Injection Molding Machine Launched

Word Games: What’s a ‘Hybrid’?

50 Years...600 Issues...and Still Counting

Integrated Injection System for Blood-Collection Tubes

PET Preform Molding Advances on Display

Complete End-to-End PET Preform Production

K 2022: ‘We’ve Been Waiting 40 Years!’

Mold Opaque White PET Bottles – Without Pigment

New Mid-Size PET Preform Machine

Advances in PET Bottle & Cap Molding at Drinktec Show

Expanded PET Preform Molding Machine Line

Injection Molding: Lubricant Coating Keeps PET Preforms Scratch-Free

Injection Molding: PET Preform Molding Machine Switches to Side Entry

How Graham Packaging Counters PCR Supply/Demand Squeeze

Blow Molding: Online PET Preform Inspection Uses AI to ‘Self-Learn’

Plastic injection molding is a cyclical manufacturing process that allows for cost-efficient production of a mass number of identical parts made from either thermoplastic or thermoset materials.

How to Improve Consistency in Injection Molding?

Cushion values in injection molding ultimately are an indication of a part’s quality, especially its dimensions. A consistent cushion will create consistent part dimensions.

How to Get Rid of Bubbles in Injection Molding?

It is important to determine which type of bubble your part has, and what the root cause might be. Determining bubble type will allow you to pinpoint the source and determine your next course of action to eliminate the problem.

How can I improve my injection molding quality and productivity?

Most molders are still relying on “general-purpose” screw designs that go back 30 years. With all of the technical improvements that have been made on machines over that time, nothing has been done to improve melt uniformity. We still use “general-purpose” (GP) screws, which well-known screw designer Bob Dray wisely has called “no-purpose” screws. That is they do not melt plastic uniformly. Processing with a uniformly melted plastic would seem like a high priority, but it has seen little if any attention.

Pet Injection Mold Blowing © 2023 Gardner Business Media, Inc. Privacy Policy [Log On]