At JEC World 2023, AZoM caught up with Robert Tsai, Founder and Chairman of Swancor, on the show floor. We discussed the company's history and what it hoped to achieve at the show this year.

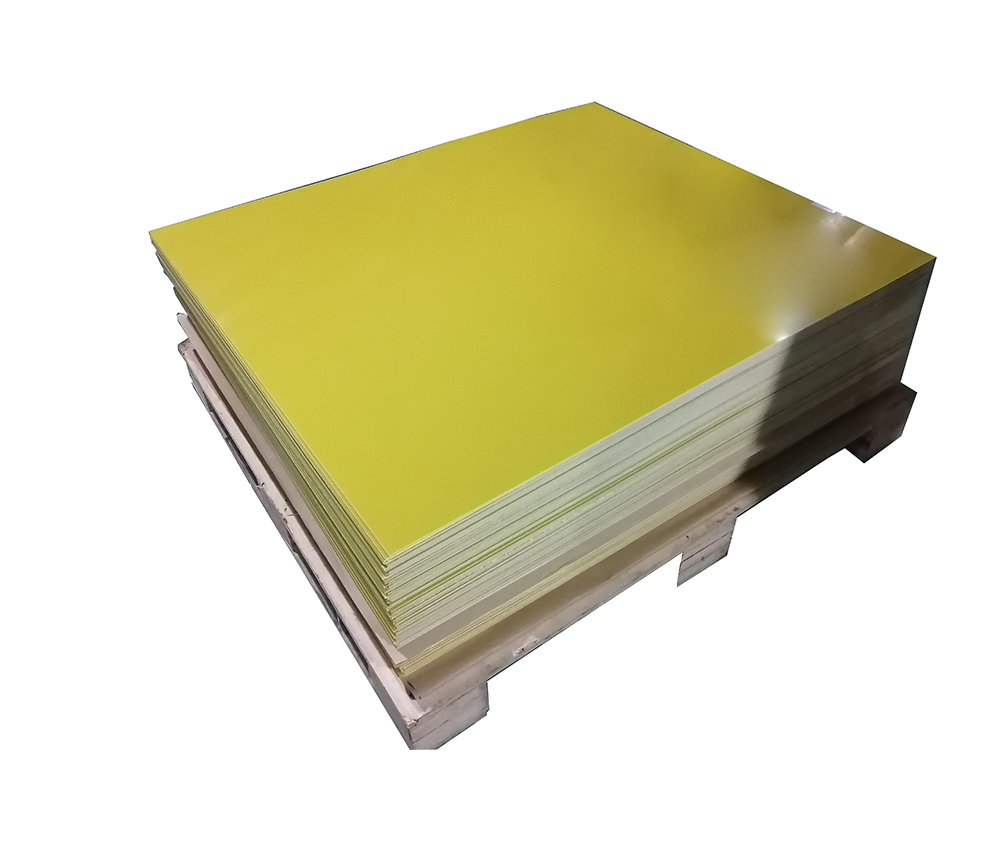

I have been involved in specialized chemical research for over 40 years. In 1992, I founded Swancor, which is dedicated to the R&D, manufacturing, and sales of environmentally friendly and green energy materials, leading the market in China and Taiwan. Subsequently, as a pioneer offshore wind power industry in Taiwan, we invested in Taiwanese offshore wind power development. G10 Glass Epoxy

In 2017, I was selected as one of the top 100 influencers in global wind power generation by the European wind power media, "A WORD ABOUT WIND." In early 2022, we launched a revolutionary, innovative product, the recyclable thermoset resin "EzCiclo," which we have been researching for years. The first " Recyclable Thermoset CFRP Composite Bike" made by the Swancor team in collaboration with our partner "GIGANTEX" was also awarded the "2023 JEC COMPOSITES INNOVATION AWARDS" by JEC World this year.

Swancor’s products are divided into three categories. The first is environmentally friendly corrosion-resistant materials, which have excellent mechanical properties, chemical resistance, processability, high strength-to-weight ratio, and fatigue resistance. They are widely used in industries such as coal power plants, electronics, automotive, marine, pipelines, and sports industries. The second is environmentally friendly green energy materials, including resins and adhesives for wind turbine blades.

These materials have excellent mechanical properties, suitable viscosity, good fiber wetting properties, and curing performance. The third is carbon fiber composites, including pultruded plates for wind turbine blade spar caps, thermoplastic epoxy sheets for the 3C and sports industries, and prepreg for industrial applications. Most importantly, Swancor has developed revolutionary, innovative products, the recyclable thermosetting materials "EzCiclo" and "CleaVER," which provide a new and effective solution to the previously unsolvable recycling problem.

Swancor has 30 years of resin development experience and production capacity in Taiwan, China, and Malaysia. Our products sell worldwide, and we achieved a revenue of €311 million in 2022.

Swancor has 660 employees, with 10% focused on research and development. Two years ago, Swancor launched SWANCOR HYVER, a resin with cost advantages and performance characteristics suitable for wind power, yacht, pultrusion, SMC/BMC, and large structural composite parts manufacture.

In 2022, Swancor launched recyclable thermosetting materials, "EzCiclo" and "CleaVER", which can reclaim both fibers and resins without generating waste solvents, emissions, or pollution (acid, alkali). "EzCiclo" and "CleaVER" are reusable, safe (compliant with EHS regulations), and have a wide range of applications, including wind turbine blades, sports, and automotive industries, and Swancor is active to expand the application in PCB and other fields.

Swancor's products can be widely used in various industries, such as wind turbine blades, marine, sports, rail transportation, electronics, large storage tanks and pipelines, and industrial anti-corrosion application.

In 2015, Swancor and Formosa Plastics Group jointly established Sunwell Carbon Fiber Composite Material (SWCFC). Sunwell combines Swancor's resin capabilities with Formosa Plastics' carbon fiber supply to provide carbon fiber composite material solutions.

Editor Skyla Baily interviews Chairman Robert Tsai at JEC World 2023

Currently, Sunwell has factories and R&D centers in Nantou, Taiwan, and Jiangsu, China. We specialize in the development and production of prepreg, thermoplastic epoxy resin sheets, and carbon fiber/glass fiber components. They are now supplying carbon pultrusion plates to global wind turbine manufacturers for the production of large wind turbine blades over 70 meters long. In 2022, we further acquired Cotech Inc., which has complete composite material structure design, analysis, and manufacturing capabilities.

It has AS9100D aerospace certification and IATF 16949 automotive certification. Its core technology is using autocalve process to produce aviation parts and automotive parts.

Composite materials, including carbon fiber composites, have many advantages compared to traditional materials. They have advantages such as high strength-to-weight ratio (lightweight and strong), corrosion resistance, design flexibility, durability, reduced maintenance, and improved energy efficiency. They are widely used in various industries, such as aviation, wind power, defense, sports and leisure, and transportation.

JEC World is the largest composite materials exhibition in Europe and even in the world. It is a global professional event for academic and product displays of composite materials, reflecting the latest technologies and application achievements in the industry. Exhibiting companies come from all over the world, and this year, Swancor brings revolutionary products, EzCiclo and CleaVER, which can solve the recycling issues of thermoset composites worldwide, making their presence indispensable.

Editor Skyla Baily and Digital Marketing Consultant Ifeyinwan Isibor from AZoNetwork meet Chairman Robert Tsai, Senior Marketing Manager Jessica Weng, and the rest of the Swancor team at JEC World 2023.

Swancor has been participating in the JEC WORLD for over 20 years, and we deeply appreciate its importance in the materials industry. Although Swancor has distributors in many countries around the world, we value our customers' needs, feedback, and after-sales service highly. In addition to online meetings with our customers and distributors, we believe that face-to-face discussions and sitting down with customers for exchanges can enhance mutual cooperation.

This occasion is also an opportunity for us to share Swancor's latest products and services and to understand our customers' short, medium, and long-term plans, so that the services we provide are more in line with the needs of this industry.

Swancor continues to deepen and develop our presence in the fields of environmental protection and green energy. Furthermore, Swancor is undergoing a transformation towards a goal of being "devoted to carbon neutrality and new materials innovation," which includes new products and businesses related to the circular economy, such as “EzCiclo” and “CleaVER” as well as upcoming low-carbon recycling technologies for carbon fiber, microwave heating recycling of carbon fiber and CCUS (carbon capture, utilization, and storage).

In addition to the applications in wind turbine blades and the sports industry, “EzCiclo” is also being utilized in other industries such as PCB and aerospace for the circular economy application of composite materials.

"EzCiclo" has not only won numerous innovation awards but has also recently collaborated with wind turbine manufacturers to successfully produce recyclable wind turbine blades. The verification of degradation and recycling has also been achieved for bicycles. Swancor has already established a recycling demonstration line in Taiwan, which can process 40 tons of recycled composite materials per year. We plan to establish a recycling demonstration line in China in 2024, which can process 2,000 tons of recycled composite materials per year. Swancor wants to find partners in Europe for circular economy initiatives.

Robert Tsai has been involved in specialized chemical research for over 40 years. In 1992, he founded Swancor, which manufactures and sells environmentally friendly and green energy materials, leading the market in China and Taiwan. As well as this, he was a pioneer of the offshore wind power industry in Taiwan.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.

Skyla graduated from the University of Manchester with a BSocSc Hons in Social Anthropology. During her studies, Skyla worked as a research assistant, collaborating with a team of academics, and won a social engagement prize for her dissertation. With prior experience in writing and editing, Skyla joined the editorial team at AZoNetwork in the year after her graduation. Outside of work, Skyla’s interests include snowboarding, in which she used to compete internationally, and spending time discovering the bars, restaurants and activities Manchester has to offer!

Please use one of the following formats to cite this article in your essay, paper or report:

Baily, Skyla. (2023, May 16). How is Swancor Developing Toward the Future?. AZoM. Retrieved on January 08, 2024 from https://www.azom.com/article.aspx?ArticleID=22660.

Baily, Skyla. "How is Swancor Developing Toward the Future?". AZoM. 08 January 2024. <https://www.azom.com/article.aspx?ArticleID=22660>.

Baily, Skyla. "How is Swancor Developing Toward the Future?". AZoM. https://www.azom.com/article.aspx?ArticleID=22660. (accessed January 08, 2024).

Baily, Skyla. 2023. How is Swancor Developing Toward the Future?. AZoM, viewed 08 January 2024, https://www.azom.com/article.aspx?ArticleID=22660.

Do you have a review, update or anything you would like to add to this article?

Dr. Craig Johnson & Dr. Kate Vanderburgh

AZoMaterials speaks with Dr. Craig Johnson, Director of Research Core Facilities, and Dr. Kate Vanderburgh, Scanning Electron Microscope (SEM) and X-Ray Microscopy Manager, about the Materials Characterization Core (MCC) facility at Drexel University.

In this interview, we speak with John Weaver from Pfizer about the importance of process safety testing.

In this interview, AZoM speaks to Bruker Optics about the different ways IR light can be used in semiconductors.

This article describes the features and applications of the Optical precision micrometer - optoCONTROL2520.

Discover the SAVANNAH Raman module, the most compact OEM Raman module.

Specac’s Power Hydraulic Press Series are available in 8 Ton, 15 Ton and 25 Ton load configurations.

The global semiconductor market has entered an exciting period. Demand for chip technology is both driving the industry as well as hindering it, with current chip shortages predicted to last for some time. Current trends will likely shape the future of the industry, which is set to continue to show

The primary distinction between graphene-based batteries and solid-state batteries lies in the composition of either electrode. Although the cathode is commonly changed, carbon allotropes can also be employed in fabricating anodes.

In recent years, the IoT is rapidly being introduced into almost all sectors, but it has particular importance in the EV industry.

AZoM.com - An AZoNetwork Site

China Epoxy Plate Owned and operated by AZoNetwork, © 2000-2024